Industrial Waste Separating Equipment

Discover Komptech’s innovative solutions for waste separation and contaminant removal, featuring advanced equipment designed to efficiently remove plastics, stones, metals, and more from waste streams. Maximize productivity and product quality while reducing environmental impact

Waste Material Separating and Contaminant Removal

![]() When you’re processing waste, the right separation equipment is critical in removing unwanted materials like rock, metal, and plastic to improve efficiency and provide a better-finished product.

When you’re processing waste, the right separation equipment is critical in removing unwanted materials like rock, metal, and plastic to improve efficiency and provide a better-finished product.

Komptech Separation Machines are engineered to remove contaminated material efficiently.

Stonefex – Stone Separation

Hurrikan S – Plastic Separation

Ballistor – Ballistic Separation. Separate out usable fractions from waste.

Hurrikan S – Windsifter Separator

Effectively removes up to 95% of contaminants.

Compatible with most commercial mobile screening units.

The Hurrikan S is a mobile, high-throughput windsifter that removes light fraction plastics, rocks and Fe-metals from screened overs using a patented “pressure-suction “process. A targeted air knife first separates material, and then lightweight material is drawn out by a powerful suction blower.

Power – CB Gen Set Tier 4 Final / 80 H

Transport Dimensions (LxWxH): 36’1″ x 8’4″ x 13’1″ (11 x 2.55 x 4 m)

Working Dimensions (LxWxH): 36’1″ x 9’10” x 13’1″ (11 x 3 x 4 m)

Weight: 22,000 lbs

Maximum Throughput Rate: up to 100 yd3/hr (76 m3/hr) up to 100 yd3/hr (76 m3 / hr)

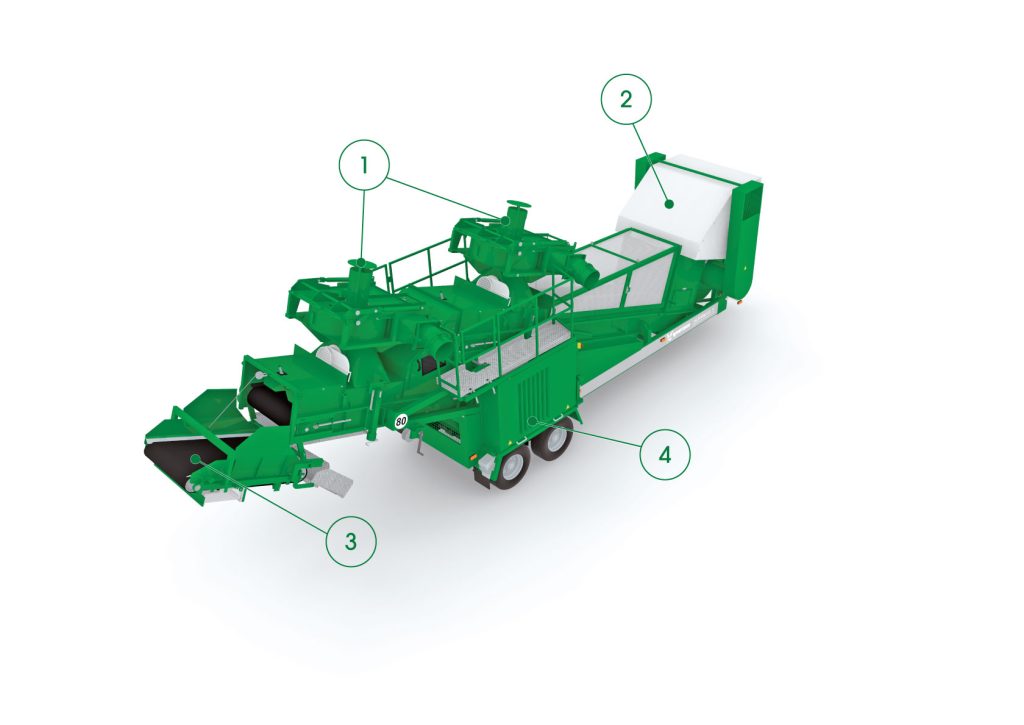

Komptech Hurrikan S Features

1 Suction Blowers

Ensure effective separation of lightweight fractions from the screen overflow with a powerful pressure-suction system with two suction blowers.

2 Vibrating Infeed

A vibrating material feeder with enclosure shakes material to keep it moving while preventing backups and increasing your throughput.

3 Efficiency Options

The Hurrikan S features an optional magnetic drum and stone separator – round, heavy objects (mostly rocks) roll down an adjustable, slope conveyor to a chute and away.

4 Simple Mobility

Gain maximum mobility thanks to four rugged wheels, simple hitch hook up, and independent operation with on-board diesel power unit.

STONEFEX Stone Separator

The Stonefex is a mobile stone separator that removes rocks and heavy inert items from materials such as preshredded green waste or compost overs. Output that was previously difficult to use due to high concentration of stones, can now be easily processed into fuel.

- Wide range of applications such as C&D, log yard cleanup, mulch and compost.

- Separate efficiently without the use of water.

Power: bJCB Gen Set Tier 4 Final / 55 HP

Transport Dimensions (LxWxH): 27’3″ x 8’4″ x 13’1″ (8.3 x 2.55 x 4 m)

Working Dimensions? (LxWxH): 27’3″ x 24’7″ x 12’2″ (8.3 x 7.5 x 3.7 m)

Weight: 22,000 lbs

Maximum Throughput Rate: (dependent on material): up to 130 yd3/hr (100 m3/hr)

Ballistor, Ballistic Separator

The 2-D fraction, like paper, cardboard, etc., is shaken clean of impurities as it passes across the screen elements, and transported upwards.

The 3-D fraction is moved downwards by the ballistic movement and removed. Variable hole sizes of the screen elements further sort the rising material to separate out the fine fraction.

An efficient electric drive system and low power requirements keep energy costs down with long service life.