Screening Equipment: Everything You Need To Know.

Choosing the correct screener will increase efficiency, improve production and lower operating and production costs for aggregate crushing, screening and recycling applications. Contact UsPrecision Screening for Sand, Gravel and More

Screening is an essential step in aggregate processing. It separates material into different sizes so it meets the strict specifications required for construction, road building, concrete, and asphalt applications. Accurate screening ensures better efficiency, reduced waste, and higher-quality finished products.

At Foreman Equipment, we provide screening solutions for every stage of your operation—whether you need precision inclined finishing screens, horizontal screens, heavy-duty scalping screens, trommel screens for sorting large rock or specialized systems like wet screens for washing or complete systems for washng and screening rock, sand and recovering fines.

The crusher produces the gradation, but the screen produces the specification. Until the crushed material is successfully screened, no money is made.

Our Core Screening Solutions

When it comes to screening aggregates, two types of screens do the heavy lifting: finishing screens and scalping screens. Finishing screens provide precise sizing for sand, gravel, and other fine materials, ensuring your final product meets strict specifications. Scalping screens, on the other hand, handle the toughest jobs—removing oversized and undersized material before crushing to protect your equipment and improve efficiency.

Inclined Screens

Inclined screens are the backbone of sand and gravel operations. Mounted at an angle, they use vibration to move material across the screen deck, separating it by size. Inclined screens are the go-to choice for high-capacity production where accuracy is critical for meeting specifications.

Key Advantages:

High throughput for bulk processing

Accurate sizing for construction aggregates

Reliable in tough conditions

Horizontal Screens

Horizontal screens operate on a flat plane and use elliptical motion for effective material movement. They provide longer material retention, making them ideal for fine screening applications or sites where space is limited.

Key Advantages:

Precise screening for fine material

Longer retention time for maximum separation

Compact design for tighter spaces

Application Specific Screens

Certain screening jobs require specialized solutions for unique processing challenges:

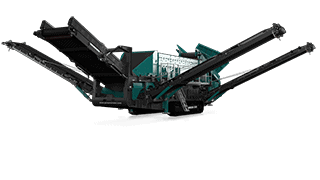

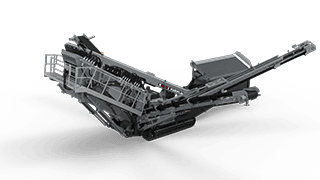

Scalping Screens

Scalping screens are the heavy-duty workhorses of aggregate processing. They remove oversized and undersized material before it enters the crusher, protecting equipment and improving efficiency. Built for large feed sizes and harsh conditions, scalping screens are indispensable in quarry and recycling operations. They’re also used for topsoil, compost, and C&D material.

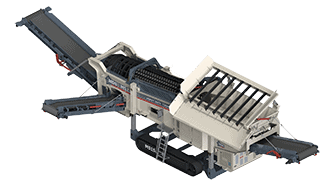

Wash Screens

Wash screens use water sprays to remove clay, silt, and other contaminants from aggregate material. They produce a cleaner, higher-quality product, essential for concrete, asphalt, and other end-use applications.

Dewatering Screens

Dewatering screens remove excess water from sand, fines, and other materials after washing. This helps reduce stockpile drying time, lowers handling costs, and produces a more consistent final product.

Frequently Asked Questions

What is screening in aggregate processing?

Screening separates material into different size fractions using vibrating screens, ensuring aggregates meet quality specifications.

Why Is Screening Important

Proper screening improves efficiency, reduces waste, and ensures material meets the size requirements for road base, concrete, and asphalt.

What is the difference between inclined and horizontal screens

Inclined screens are angled and great for high-capacity sand and gravel work. Horizontal screens sit flat and provide longer retention time for fine screening.

What does a scalping screen do?

Removes oversized and undersized material before crushing, protecting crushers and improving performance.

Why use a wash screen?

To clean aggregates by removing silt, clay, and dust, improving the quality for end-use applications.

What is the purpose of a dewatering screen?

Removes excess water after washing, creating a drier product that’s easier to handle.

When should I use a rock trommel screen

When you need to pre-sort large, irregular rock before further screening or processing.

Learn More About Our Brands.

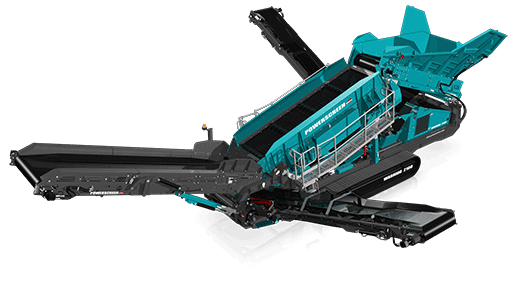

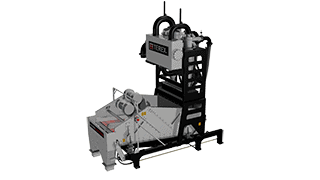

Track Mounted or Wheeled Portable Washing Screens

- Terex Washing Screens

- Integrated feed hopper and onboard discharge conveyors

- Quick set up time, typically under 15 minutes

Are you looking for a fast, reliable way to screen rock, stone, sand, gravel and crushed concrete?

Warrior 1200 4′ x 12′ 2-Deck Screen

Look no further – our mobile track mounted screening equipment is the perfect solution.

With nearly forty years of crushing and screening experience, we can confidently say that it’s the most efficient and effective option available.

![]() Downloads

Downloads

Mobile track-mounted screens add mobility, versatility, and adaptability.

Mobile track mounted screeners are the most efficient method of screening large quantities of material.

• Self-Contained – No outside power required.

• Track-Mounted – Able to move over difficult terrain.

• Smaller Footprint – Access sites with limited or confined space.

• Rapid Mobility- Sets up in minutes, not hours.

• Site set up & training included.

Are you screaming the screening blues?

Our team is ready to help you accomplish more by delivering industry and product expertise combined with world-class parts and service support. How can we help you?