From Quarry to Jobsite, Our Jaw Crushers Deliver Unmatched Power and Versatility.

Mobile jaw crushers are a proven solution for crushing hard abrasive rock, stone, concrete, asphalt and other materials in pits, quarries, and on construction sites.

High-Performance Jaw Crushers for Aggregate Mining and Recycling.

What Is a Jaw Crusher?

A jaw crusher is a machine that’s built to handle tough jobs. It breaks down hard materials like rock, stone, concrete, and ore by using compressive force. It works like a giant nut cracker Picture two heavy-duty surfaces squeezing the material until it cracks into smaller pieces.

Jaw crushers are a favorite in industries like quarrying, mining, and recycling because they’re tough, reliable, and easy to use. With their big, rectangular openings and ability to crush just about anything—including hard materials like granite and bauxite—they’re perfect for primary crushing and concrete recycling.

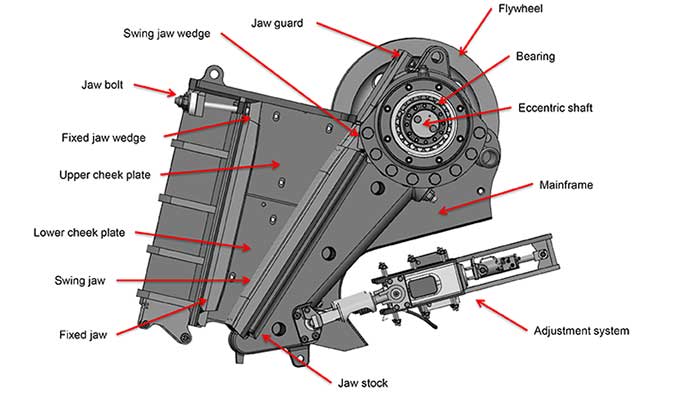

The Crushing Chamber: Where the Action Happens

The crushing chamber is where the magic happens. This V-shaped cavity is formed by two jaws: one stays still (the fixed jaw), and the other moves back and forth (the swing jaw).

The swing jaw is powered by an eccentric shaft that keeps it constantly in motion—opening and closing, chewing through the material. It’s a simple design, but that’s what makes it so effective.

How Jaw Crushers Work.

Jaw crushers work with a simple but powerful process. Big chunks of rock or other materials are dropped into the feed opening at the top. Once inside, the material gets trapped between two jaws: one that stays in place and one that moves.

As the swing jaw presses against the material, it crushes it into smaller pieces. The chamber is designed like a funnel, getting narrower as the material moves downward. By the time it reaches the bottom, it’s small enough to pass through the opening, called the closed side setting (CSS). The CSS is the smallest size the jaw crusher is set to produce.

This process keeps repeating—crushing, moving, and releasing—until there’s a steady flow of material that’s just the right size. It’s a straightforward system, but it’s incredibly efficient and reliable, making jaw crushers a must-have for breaking down hard materials.

“Crushing It” Starts with the Right Choice

Not all jaw crushers are created equal, and the stakes are high when choosing the right one for your operation. Are you wrestling with oversized, abrasive materials? Struggling to hit production targets? Or maybe downtime is eating into your profits? Every operation is different, and so are the challenges. That’s why it’s crucial to pick a jaw crusher that matches your needs—not just today, but for the long haul. At Foreman Equipment, we know these decisions can be daunting, but we’re here to simplify the process and help you make the right call.

Powerscreen Premiertrak Jaw Crushers

Powerscreen® Premiertrak jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries. These machines are the most advanced and reliable in the market and are highly productive in a variety of applications.

Powerscreen® Premiertrak jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries. These machines are the most advanced and reliable in the market and are highly productive in a variety of applications.

Premiertrak 330 Jaw Crusher

The Premiertrak 330 has a two-piece grizzly feeder allowing better material flow to the crusher and a variable crusher speed that allows the operator to fine-tune the machine for optimized crushing performance.

A hydrostatic drive system offers versatility and allows the crusher to be operated in reverse, of particular benefit in recycling applications.

Specifications

Output Potential: up to 280tph (308 US tph)

Transport Dimensions: Width: 8’6″ Length: 51′ Height: 11’1”

Working Dimensions: Width: 15’1″ Length: 51′ Height: 13′

Weight: 76,853lbs with side conveyor and magnet

CSS Range: Recycling Min: 1.5″ Quarry Min: 2″ Max: 5″

- Output potential up to 280tph (308 US tph) (Depending on application & CSS)

- Hydrostatic Drive with reverse crush capacity

- Heavy duty wear resistant feed hopper

- Stepped self-cleaning grizzly feeder with under feeder screen

- Wide bypass chute to optimise material flow

- Aggressive crushing action with high swing jaw encouraging material entry into crushing chamber

- Fully hydraulic crusher setting adjustment

- Improved manganese liner retention, protects jaw supports on both swing & fixed jaws

- Excellent under crusher access for removal of wire with hydraulic raise/lower product conveyor (Optional)

- Low fuel consumption due to efficient drive system and low engine RPM

- Easily accessed power unit canopy

- PLC control system with auto start facility

- Remote control via umbilical

- Dust suppression system

- Hydraulic deflector plate

- Bypass conveyor

- Single pole/twin pole magnet

- Radio remote control

- Belt weigher

- Extended hopper

- Hydraulic water pump

- Deflector plate adjustment

Premiertrak 400X Jaw Crushers

The Powerscreen® Premiertrak 400X range of portable jaw crushers is designed for medium-scale aggregate, mining, and recycling applications.

The range includes the Premiertrak 400X with hydraulic adjust and the Premiertrak R400X with hydraulic release. User benefits include track mobility for a quick set-up time (typically under 30 minutes,) hydraulic crusher setting adjustment for total control of product size and crusher overload protection to prevent damage by uncrushable objects.

| Specificatijon | Value |

|---|---|

| Output Potential | 400tph (441 US tph) |

| Transport Dimensions | Width: 9’2″ Length: 51’10” Height: 11’2″ |

| Working Dimensions | Width: 16’5″ with side conveyor Length: 51’2″ Height: 13’7″ |

| Weight | Tier 3: 102,515lbs, Tier 4F: 102,846lbs, Tier 4F Pre-Screen: 105,888lbs |

| CSS Range | Min: 2″ Max HA: 5.6″ Max HR: 6″ |

- Output potential up to 280tph (308 US tph) (Depending on application & CSS)

- Hydrostatic Drive with reverse crush capacity

- Heavy duty wear resistant feed hopper

- Stepped self-cleaning grizzly feeder with under feeder screen

- Wide bypass chute to optimise material flow

- Aggressive crushing action with high swing jaw encouraging material entry into crushing chamber

- Fully hydraulic crusher setting adjustment

- Improved manganese liner retention, protects jaw supports on both swing & fixed jaws

- Excellent under crusher access for removal of wire with hydraulic raise/lower product conveyor (Optional)

- Low fuel consumption due to efficient drive system and low engine RPM

- Easily accessed power unit canopy

- PLC control system with auto start facility

- Remote control via umbilical

- Dust suppression system

- Hydraulic deflector plate

- Bypass conveyor

- Single pole/twin pole magnet

- Radio remote control

- Belt weigher

- Extended hopper

- Hydraulic water pump

- Deflector plate adjustment

Premiertrak 450R Jaw Crusher

Crush Your Day

The Powerscreen® Premiertrak R450 is a high-performance primary jaw crusher designed for medium-scale operations in quarrying, demolition, recycling, and mining. With an output potential of up to 450 tph, it features a robust single-toggle jaw with a 28″ x 44″ 700mm x 1100mm feed opening for aggressive crushing action. The machine boasts advanced features like a hydraulic setting adjustment, hydraulic release chamber for uncrushables, and low fuel consumption due to its efficient direct drive system.

Key benefits include a heavy-duty wear-resistant feed hopper, wide bypass chute, self-cleaning grizzly feeder, and dust suppression system. Equipped with remote operation and Powerscreen Pulse telemetry, the Premiertrak R450 offers user-friendly control and real-time performance data. Ideal for handling aggregates, C&D waste, river rock, and processed ores, it ensures efficiency and reliability for demanding applications.

| Specification | Value |

|---|---|

| Output Potential | 450 tph |

| Transport Dimensions | Width: 9’2″ Length: 52’10” Height: 11’2″ |

| Working Dimensions | Width: 20’9″ with side conveyor Length: 52’2″ Height: 16’1″ |

| Weight | Tier 108,302lbs, |

| CSS Range (Rec) | Min: 2″ 5.6″ Max 5.6″ |

| CSS Range (Quar) | Min: 3″ Max 5.6″ |

- Output potential up to 450 tph (504 US tph) (Depending on application & CSS)

- Hydraulic folding feed hopper with hydraulic wedge fixing system

- Heavy duty wear-resistant feed hopper

- Stepped self-cleaning grizzly feeder with under-screen as standard

- Wide bypass chute to prevent material blockages

- Aggressive crushing action with high swing jaw encouraging material entry into crushing chamber

- Hydraulic crusher setting adjustment

- Crusher unblocking system (optional)

- Hydraulic raise / lower facility on the product conveyor to aid rebar clearance and maintenance

- HR – Hydraulic release chamber allows for uncrushables to pass through the chamber protecting it from any possible damage

Premiertrak 600 Jaw Crushers

Built for the toughest of applications, the robust construction and modern design of the Premiertrak 600 Jaw Crusher ensures optimum performance, reliability, and efficiency. The Premiertrak 600 is designed for large and medium scale operators in quarrying, demolition, recycling, and mining applications. It comes equipped with the advanced high performance 1200mm x 820mm (47’’ x 32’’) Terex chamber.

| Specification | Value |

|---|---|

| Output Potential | 600tph (661 US tph)* / 600tph (661 US tph)* |

| Transport Dimensions | Width: 9’10” Length: 56’1″ Height: 12′ 6″ / Width: 3m Length: 17.1m Height: 3.8m |

| Working Dimensions | Width: 26’5″ with side conveyor Length: 54’7″ Height: 14′ 9″ / Width: 8.05m Length: 16.63m Height: 4.49m |

| Weight | 162,701lbs / 73,800kg |

| CSS Range | Min: 3″ Max: 8″ / Min: 75mm Max: 200mm |

- Output potential up to 600tph (661 US tph) (Depending on application & CSS)

- Ground level quick set-up with hydraulic folding feed hopper with hydraulic locking system

- Heavy duty wear resistant feed hopper

- Stepped self-cleaning grizzly feeder with under feeder screen

- Wide bypass chute to optimise material flow

- Aggressive crushing action with high swing jaw encouraging material entry into crushing chamber

- Fully hydraulic crusher setting adjustment

- Excellent under crusher access for removal of wire with hydraulic raise lower product conveyor

- Angle adjustable product conveyor, lowers for access & transport

- Low fuel consumption due to highly efficient direct drive system and low engine RPM

- Easily accessed power-unit canopy

- Modern & user-friendly PLC control system with auto start facility

- Remote control via umbilical

- Dust suppression system

- Fitted with Powerscreen Pulse Telematics system

- Pre-screen system

- Wire mesh for underscreen (standard)

- Quarry tooth, pyramid tooth or heavy duty fixed jaw plates

- Deflector plate under crusher

- Side conveyor

- Single pole overband magnetic separator

- Twin pole overband magnetic separator

- Belt weigher

- Electric refuelling pump

- Electric urea pump

- Hydraulic water pump

- Radio remote control

- Stockpiler drive (Tier 4 machines only)

Download

Metrotrak Jaw Crusher

The Powerscreen Metrotrak is a highly compact, high performing tracked mobile jaw crushing plant featuring the “M” series single toggle jaw crusher. The new Metrotrak builds on the previously successful model with upgraded features, additional options, and slick new styling. It includes an aggressive crushing action and a high output even in tight settings. The Metrotrak is ideally suited to operators in the mining, quarrying, and recycling industries; especially those working in urban locations or where space is restricted.

| Specificatijon | Value |

|---|---|

| Output Potential | 200tph (220 US tph) depending on the application |

| Transport Dimensions | Width: 7′ 10″ Length: 40’ 8’’ Height: 10’ 6” |

| Working Dimensions | Width: 12’ 6” Length: 40’ 8” Height: 10’ 6” |

| Weight | 62,170lbs (Tier 3) – 61,729lbs (Tier 4) |

| CSS Range | Recycling Min: 1.5″ Quarry Min: 2″ Max: 5.25″ |

- Output potential up to 600tph (661 US tph) (Depending on application & CSS)

- Ground level quick set-up with hydraulic folding feed hopper with hydraulic locking system

- Heavy duty wear resistant feed hopper

- Stepped self-cleaning grizzly feeder with under feeder screen

- Wide bypass chute to optimise material flow

- Aggressive crushing action with high swing jaw encouraging material entry into crushing chamber

- Fully hydraulic crusher setting adjustment

- Excellent under crusher access for removal of wire with hydraulic raise lower product conveyor

- Angle adjustable product conveyor, lowers for access & transport

- Low fuel consumption due to highly efficient direct drive system and low engine RPM

- Easily accessed power-unit canopy

- Modern & user-friendly PLC control system with auto start facility

- Remote control via umbilical

- Dust suppression system

- Fitted with Powerscreen Pulse Telematics system

- Pre-screen system

- Wire mesh for underscreen (standard)

- Quarry tooth, pyramid tooth or heavy duty fixed jaw plates

- Deflector plate under crusher

- Side conveyor

- Single pole overband magnetic separator

- Twin pole overband magnetic separator

- Belt weigher

- Electric refuelling pump

- Electric urea pump

- Hydraulic water pump

- Radio remote control

- Stockpiler drive (Tier 4 machines only)

Gladiator PT400 Wheeled Jaw

The Gladiator PT400 is a new electrically driven, wheeled jaw crusher. It features the tried-and-tested JW42 3042 jaw-crusher and is chassis mounted on wheels meaning ease of movement and set-up.

Specifications

| Output Potential | 463 US tph (420 tph) |

| Transport Dimensions | Width: 3.43m Length: 15.93m Height: 4.14m |

| Working Dimensions | Width: 3.43m Length: 15.93m Height: 4.8m |

| Weight | 48,625kg |

| CSS Range | Min: 45mm Max: 145mm |

Evoquip Bison Compact Jaw Crushers

Compact enough for the job site, with enough production for the quarry.

Bison compact jaw crushers have a smaller footprint but don’t sacrifice production. They transport easily, set up fast, and are easy to operate, allowing producers to crush rock, stone, concrete and asphalt on the Jobsite or in the pit or quarry.

Bison compact jaw crushers have a smaller footprint but don’t sacrifice production. They transport easily, set up fast, and are easy to operate, allowing producers to crush rock, stone, concrete and asphalt on the Jobsite or in the pit or quarry.

Bison 35

The Bison 35 is a small jaw crusher, providing an ideal solution for construction companies and contractors who want to recycle their construction and demolition waste onsite. The ability to adjust the jaw setting and operate the plant fully from the remote control allows for a fast and simple setup for the customer

Specification Value

Transport Length 14′ 7″

Transport Width 4′ 11″

Transport Height 6′ 9″

Jaw Inlet 19″ x 10″

Output Potential 30 tph

Bison 120

The Bison 120 is a compact jaw crusher has been specifically designed for operators for whom versatility, maneuverability and transportability are of key importance. It is compact enough to fit inside a container for transport but strong enough to withstand the toughest of applications

Specification Value

Transport Length 18′ 4″

Transport Width 7′ 6″

Transport Height 9′

Jaw Inlet 27″ x 16″

Output Potential 80 tph

Bison 160

The Bison 160 Hybrid hook-lift jaw crusher is an ideal crusher for waste contractors who can utilize existing hook-lift vehicles to either bring material to depot for processing or alternatively bring the crusher to the waste on site – turning waste into profit whilst providing excellent productivity and fuel efficiency.

Specification Value

Transport Length 22’ 8”

Transport Width 7’ 7”

Transport Height 8’ 2”

Jaw Inlet 28″ x 20″

Output Potential 100 tph

Bison 280

The Bison 280 a compact and aggressive portable jaw crusher featuring the proven Terex ‘900mm x 600mm’ single toggle jaw crusher. This machine utilizes an extremely fuel efficient and powerful ‘Direct Drive’ system to power the crusher which provides excellent performance in recycling, contracting and quarrying industries. Its compact size, quick set-up times, ease of transport and user friendly control system makes the Bison 280 the ideal solution for all small to medium sized operators.

Specification Value

Transport Length 40′ 8″

Transport Width 7′ 10″

Transport Height 10′ 6″

Jaw Inlet 36″ x 24″

Output Potential 200 tph

Evoquip also manufactures Cobra Impact Crushers, Colt inclined screens and Harrier Scalping screens.

Ready to Crush It?

Choose the Jaw Crusher That’s Built for Your Needs.

Contact Foreman Equipment today to discuss your needs and receive a Free Quote.

Call 1-888-852-9021 or Complete the attached form.