The Ultimate Guide to Cone Crushers

Choosing the right cone crusher can elevate your secondary and tertiary crushing to the next level. Contact Us

What are cone crushers?

Cone crushers are another style of crusher that uses compression to reduce the size of the rock, construction rubble or other hard materials. Like different styles of compression crushers, these machines can accept very hard and abrasive materials.

They are most often used in the secondary or tertiary crushing stages, providing a high reduction ratio – 4:1 or 6:1 and producing a better cubical-shaped finished product.

How cone crushers work.

Crushing chamber

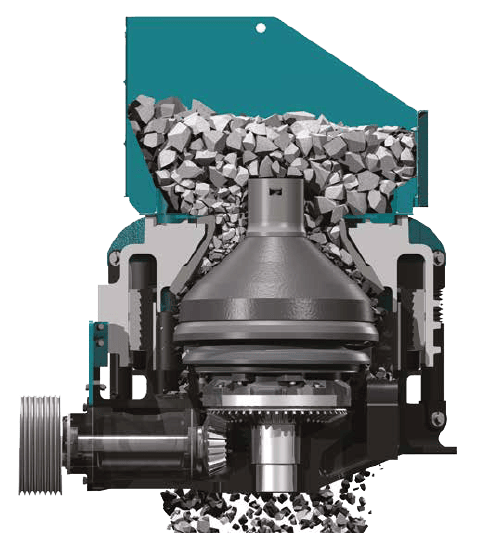

Cone crushers consist of a fixed concave and a mantle that gyrates in an eccentric motion.

The mantle is continuously moving and provides a constantly changing gap at the bottom of the crushing chamber. The smallest size of the gap is known as the closed side setting (CSS) and represents the smallest size of material that can be crushed. The largest opening is the open side setting (OSS) and represents the largest size of material that can be crushed.

The material being crushed is caught between the mantle and concave, where it is compressed with enough force to fracture and break. The material stays inside the crushing chamber until it is crushed fine enough to fall through the gap at the bottom of the crusher.

Learn more about our Cone Crushers

Do you need more information or a quote?

Fill out the form to the right and one of our Team Members will be in touch.