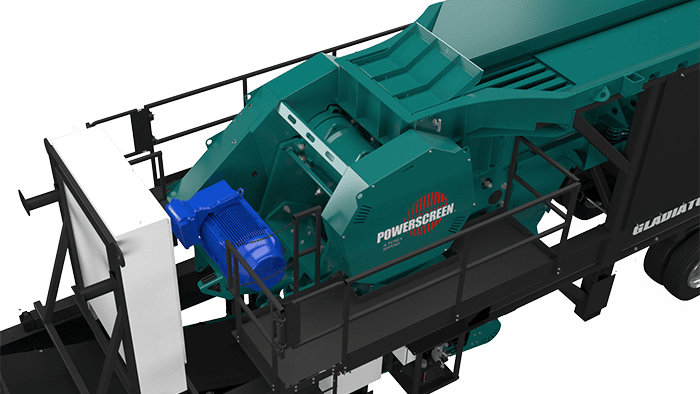

Powerscreen Gladiator PT400 30x42 Portable Jaw Crusher

Rugged. Road-Ready. Electrically powered for high-output crushing wherever you need it. Ideal for primary applications in aggregates, recycling, and roadbuilding. Get A QuoteDownload The BrochureCrushing Power

Built to Perform. Designed to Move.

The Gladiator PT400 combines the legendary durability of the Terex JW42 jaw with a modern portable design. Its 30×42″ feed opening swallows large material with ease, while the vibrating grizzly feeder removes fines before they reach the chamber—keeping production high and wear low.

Powerful Output

- Up to 420 TPH (Depending on feed material and settings)

Proven Jaw Performance

- Delivers aggressive crushing and efficient material reduction.

Precision Control

- Powerful 150 HP electric drive with precise chamber control and reverse functionality

Crush It Anywhere With Confidence

Powerscreen Gladiator PT400 30×42 Portable Jaw Crusher

Mobility Meets Muscle. Whether you’re producing sand and gravel, recycling concrete, or building roads, the Gladiator PT400 delivers serious primary crushing power—wherever the job takes you. Built on a road-legal, wheel-mounted chassis and engineered for high-volume output, this electric jaw crusher is ready to roll.

Ready to Work. Easy to Move.

Portable Performance with Serious Throughput

The Gladiator PT400 is ideal for operations that need maximum uptime with minimum fuss. From demolition sites and quarries to recycling yards, it’s built to deliver high production where space and mobility matter.

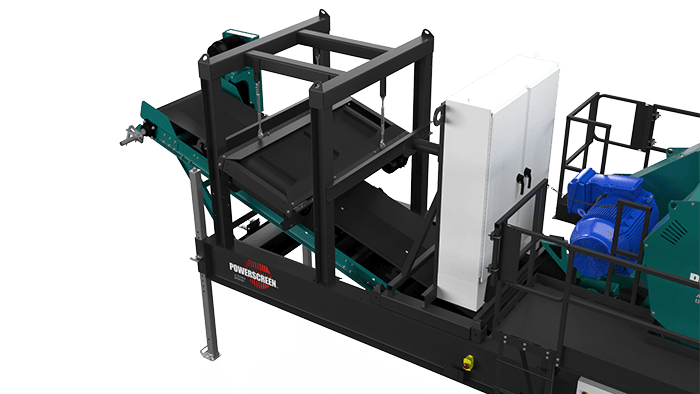

Reliable and Easy to Operate

- Simple, reliable push-button controls

- Vibrating grizzly feeder removes fines before crushing

- Aggressive crushing action by renowned JW42 jaw chamber

- Hydraulic adjustments at ground level

- Access platforms and emergency stops on both sides of the machine for safe operation

Road-Legal and Easy To Move

- North American made with the lowest weight for ease of movement.

- Heavy-Duty triaxle chassis and wheels, spring-suspension and air brakes as standard

Environmentally Friendly

- Electrically driven by either an external genset or 3-phase mains connection.

- No costly engine after treatment reducing expensive engine maintenance costs

Technical Specifications

Gladiator PT400 – 30×42″ Portable Jaw Crusher

Jaw Chamber

- Type: Terex JW42 Single Toggle

- Feed Opening: 42” x 30” (1070mm x 760mm)

- Max CSS: 5¾” (145mm)

- Min CSS:

• 1¾” (45mm) for demolition & recycling

• 2½” (60mm) for soft rock

• 3″ (75mm) for hard rock - Drive: 150 HP (112kW) electric motor @ 1200rpm

- Lubrication: Grease

Feeder & Hopper

- Vibrating Grizzly Feeder

- Standard Grizzlies:

• 4” opening with 5 bars - Optional Grizzlies:

• 2”, 3”, 5” options available - Hopper: ¾” (20mm) AR400 steel

- Extensions: 20” (500mm) AR400 optional

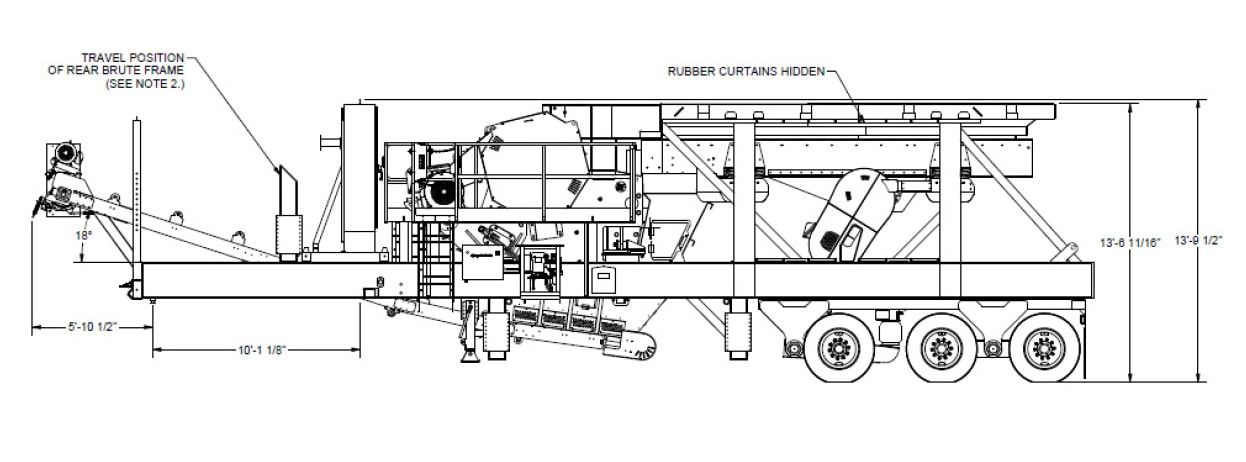

Weights and Dimensions

Length: 52′ 3″ (15.9 m)

Width: 11′-6″ (3.43 m)

Height: 15′ 9″ (4.8m)

Total Weight: 96,200lbs (43,700kg)

Axle Load: 58,100lbs (26,410kg)

King Pin Load: 38,100lbs (17,320kg)

Ready to Crush?

Call Now to Get the Gladiator on Your Site

Whether you need to rent or own, we can help you bring powerful primary crushing to your operation.

📞 Call Us Today 1-888-852-9021 or 📩 Request a Quote to get started.

Rugged Reliability + Smart Efficiency

Portable Producers Love It For a Reason

Built in North America and purpose-built for North American producers, the Gladiator PT400 checks all the boxes:

✅ Primary Crushing Power for Sand & Gravel, Concrete Recycling, and Roadbuilding

✅ Designed for Transport – fits legal load specs and is easy to reposition

✅ Cleaner Operation – electric drive eliminates the need for costly diesel servicing

✅ Ready for High-Dust & High-Altitude applications where other crushers struggle

See the PT400 In Action Crushing Blast Rock

Crushing Made Simple.

With the Gladiator PT400, you’re not just buying a jaw crusher—you’re investing in production, uptime, and long-term value.