Filterpress Systems for Water Recovery & Sludge Dewatering

Reclaim up to 95% of your process water and reduce waste disposal costs with a fully automated, zero-hydraulics filterpress system built for aggregates, recycling, and C&D operations. See Models & SpecsRequest a Quote.Take Control Of Your Wastewater.

Still managing sludge ponds? You’re wasting water, space, and money.

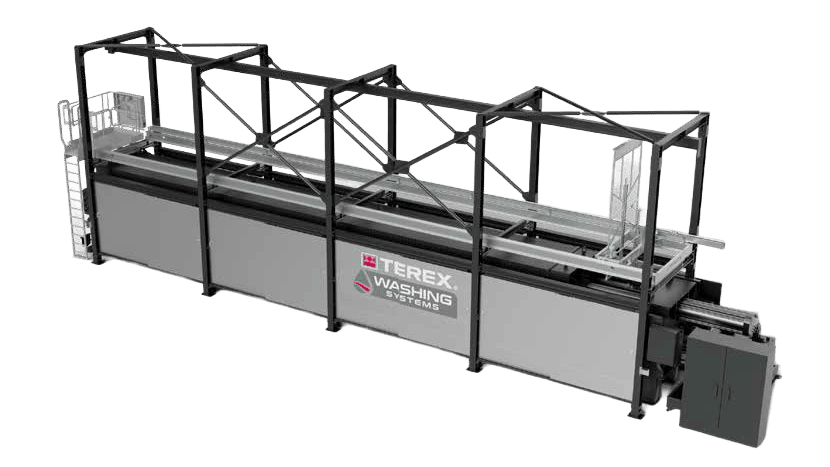

The Terex Washing Systems Filterpress is a compact, automated solution that quickly and efficiently turns thickened slurry into dry solids.

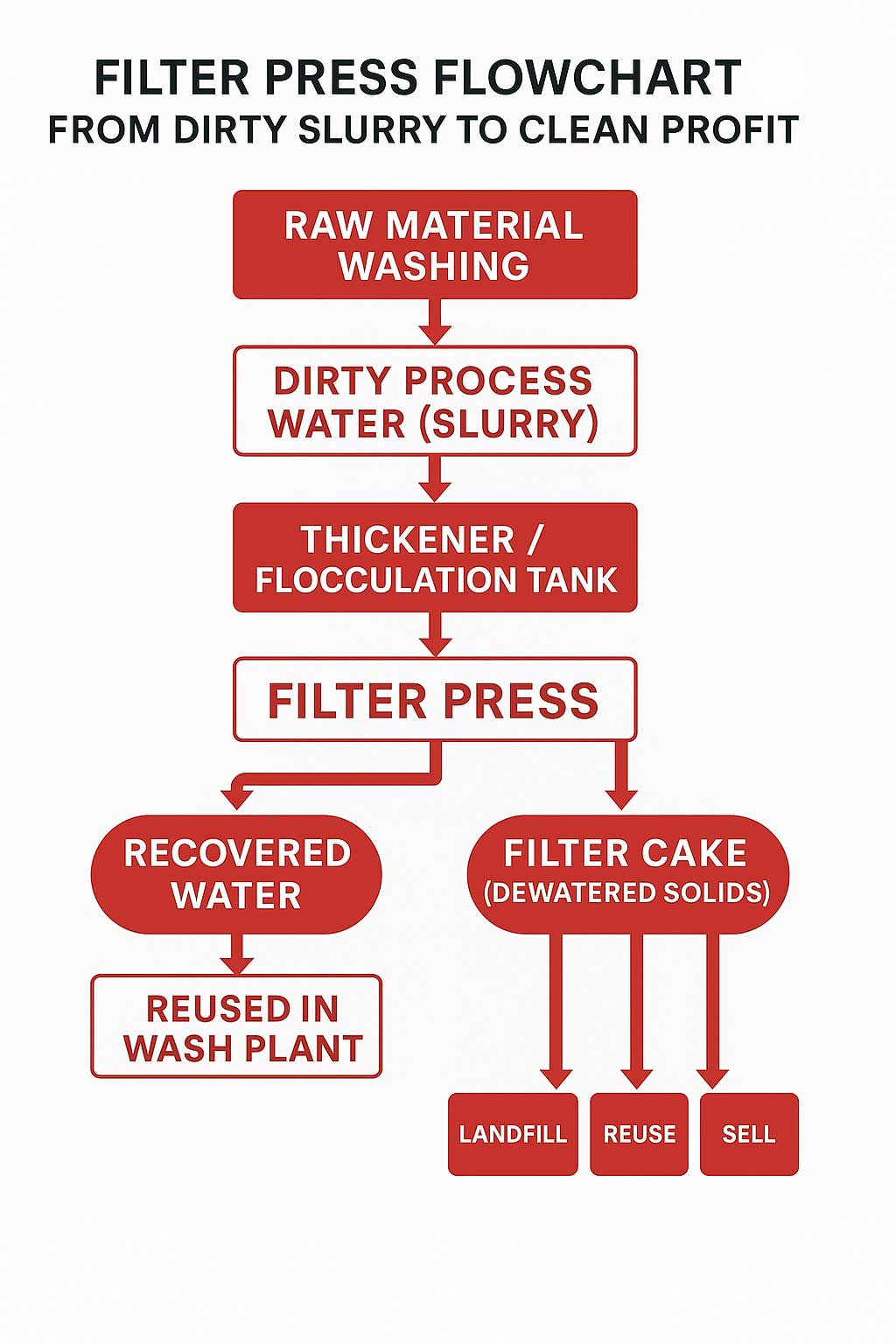

From Dirty Slurry to Clean Profit: Here’s How

After thickening, slurry is pumped into the filterpress, where it’s compressed into dry cake. Clean water is returned to your system. No pond required.

Key Benefits:

√ Recover up to 95% of water for reuse

√ Create dry solids with up to 85% dryness

√ Eliminate hydraulic mess with belt-driven design

√ Automate cleaning with built-in cloth wash system

√ Cut disposal and hauling costs

√ Minimize your footprint — perfect for urban sites

Models & Technical Specs

Insert a clean table comparing:

| Model | Plate Size | # Plates | Filtration Area | Tons/Cycle | Working Pressure |

|---|---|---|---|---|---|

| FP1500 | 1500×1500 | 45–135 | 167–510 m² | 5.2–15.9 mtph | 15 bar (218 psi) |

| FP2015 | 2000×1500 | 45–165 | 223–832 m² | 9.5–35.6 mtph | 15 bar (218 psi) |

| FP2000 | 2000×2000 | 45–165 | 309–1150 m² | 12.1–45.3 mtph | 15 bar (218 psi) |

Who It’s Built For

🧱 Aggregate Producers

Cleaner material, less water use

♻️ Recycling Yards

Drier solids = cheaper disposal

🏗️ Urban C&D Sites

Compact footprint, easy setup

🌍 Sustainability-Focused Sites

Reduce environmental impact

Get a Cleaner Operation: Without the Headaches.

Call: 1-888-852-9021

Request a quote.

Talk to our team.

Request a call back.

Download the TWS Aquaclear

Water Management Brochure.