The Ultimate Guide to Cone Crushers

Choosing the right cone crusher can elevate your secondary and tertiary crushing to the next level. Contact UsWhat are cone crushers?

Cone crushers are another style of crusher that uses compression to reduce the size of the rock, construction rubble or other hard materials. Like different styles of compression crushers, these machines can accept very hard and abrasive materials.

They are most often used in the secondary or tertiary crushing stages, providing a high reduction ratio – 4:1 or 6:1 and producing a better cubical-shaped finished product.

How cone crushers work.

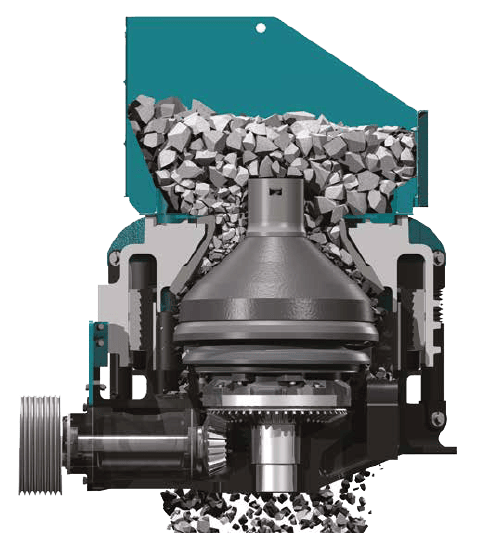

Crushing chamber

Cone crushers consist of a fixed concave and a mantle that gyrates in an eccentric motion.

The mantle is continuously moving and provides a constantly changing gap at the bottom of the crushing chamber. The smallest size of the gap is known as the closed side setting (CSS) and represents the smallest size of material that can be crushed. The largest opening is the open side setting (OSS) and represents the largest size of material that can be crushed.

The material being crushed is caught between the mantle and concave, where it is compressed with enough force to fracture and break. The material stays inside the crushing chamber until it is crushed fine enough to fall through the gap at the bottom of the crusher.

Learn more about our Cone Crushers

Maxtrak Cone Crushers – Designed for Mobility and Maximum Productivity.

The Maxtrak range of cone crushers from Powerscreen have been designed and engineered with an eye on maximum productivity, which is the cornerstone of the highly successful Powerscreen philosophy.

The Maxtrak range of cone crushers from Powerscreen have been designed and engineered with an eye on maximum productivity, which is the cornerstone of the highly successful Powerscreen philosophy.

Powerscreen Maxtrak cone crushers are suitable for crushing a wide range of materials, medium to fine crushing ratios and continuous feed grinding. The machine offers the most flexible design of any cone crusher, meaning it can be used as a secondary or tertiary crusher in a wide range of aggregate and recycling applications.

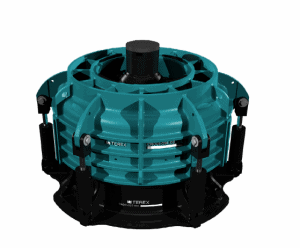

Automax Cone Crusher – The Heart of Maxtrak

The heart of the Maxtrak crushing plant is the Automax® cone crusher with hydraulic setting, (1) Tramp Iron Release, and (2) Unblocking System. Its unique crushing action provides excellent capacity, high reduction, and good product cubicity to produce high-quality aggregate and sub-base materials.

- Tramp Iron Release is a safety feature. Tramp iron refers to any unwanted metal piece, like a bolt or a piece of steel, that accidentally gets mixed with the material being crushed. These pieces can cause damage to the crusher. The tramp iron release feature allows the crusher to adjust automatically to let this unwanted metal pass through without causing damage. Think of it like a safety valve that opens up when something too hard to crush comes along.

- Unblocking: Sometimes, the material in the crushing chamber can get stuck or block the crusher, stopping it from working correctly. The unblocking feature helps quickly clear these blockages without manually removing the stuck material, which keeps the crusher running smoothly and reduces downtime.

Fast Set Up, Easy to Move, Better Production

Powerscreen 1150 Maxtrak Setup

From the ground up, the Maxtrak® has been designed to improve productivity and facilitate setup and operation.

- Hydraulic-assisted conveyor positioning.

- Hopper setup enables fast setup and rapid mobility.

- Easy access maintenance and inspection platforms.

- Easy access to the engine, crusher and feed conveyor.

- Remote radio track controls are standard.

- Variable-speed belt feeders with integral hoppers

- Hydraulic raise and lower feed assemblies for transport and cone access for liner changes.

- Can be fed with full-level control from a conveyor, bucket loader or excavator.

Maxtrak Mobile Cone Crushers

As the largest Powerscreen Dealer in Western Canada, we are proud to offer the full line of Powerscreen Maxtrak Cone Crushers for sale or rent.

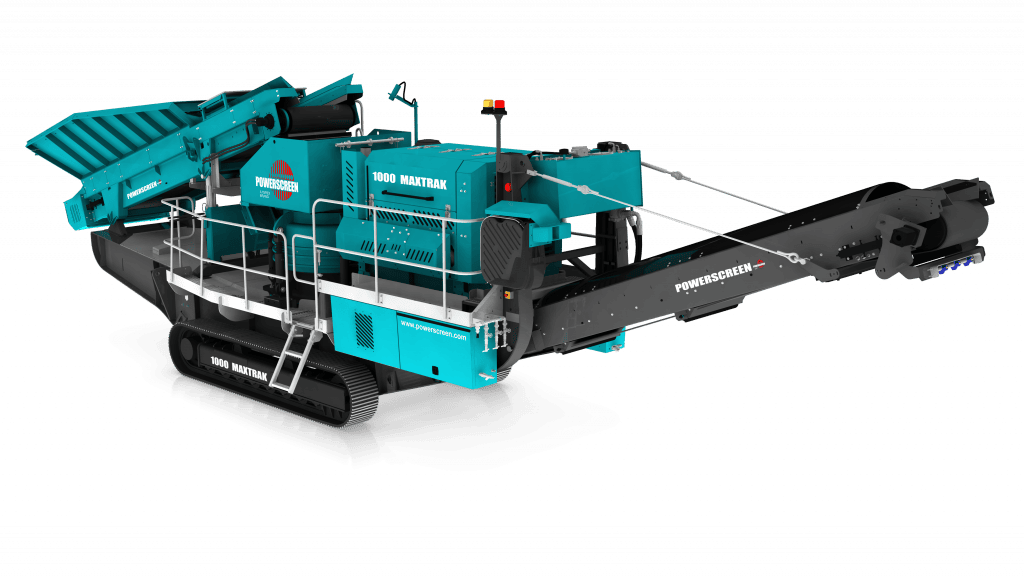

1000 Maxtrak

The high performance Powerscreen® 1000 Maxtrak portable rock crusher has been designed for direct feed applications without pre-screening on clean rock. At the heart of the Maxtrak is the Automax cone crusher with hydraulic setting, tramp release, and unblocking system. Its unique crushing action provides excellent capacity, high reduction, and good product cubicity for the production of high quality aggregate and sub-base materials. This machine comes standard with Powerscreen Pulse and operates economically with a highly fuel efficient system.

| Output Potential | 230tph (253 US tph)* |

| Transport Dimensions | Width: 9’2″ Length: 47’11” Height: 11’4″ |

| Working Dimensions | Width: 11’4″ Length: 47’11” Height: 13’5″ |

| Weight | Tier 3: 67,108lbs Tier 4: 70,151lbs |

| CSS Range | Min: 0.7″ Max: 1.6″ |

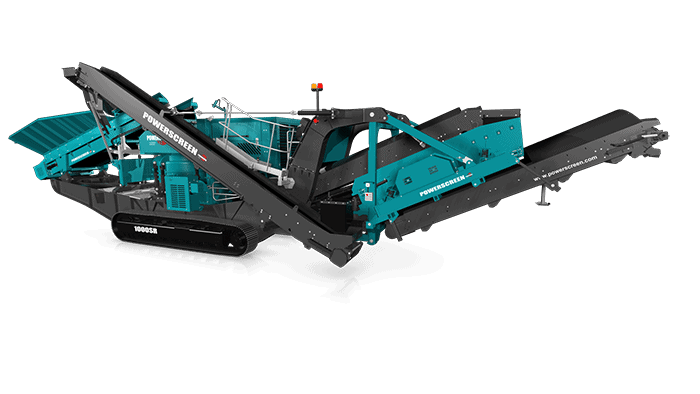

1000 Maxtrak SR

The Powerscreen® 1000SR mobile cone crusher is built around the successful 1000 Maxtrak model and features a re-circulating conveyor and a double-deck post-screen to provide a complete crushing and screening process on a single chassis. The machine is designed for direct feed applications without pre-screening on clean rock.

| Output Potential | 230tph (253 US tph)* |

| Transport Dimensions | Width: 10’2″ Length: 55’ 5” Height: 11’4″ |

| Working Dimensions | Width: 11’3″ Length: 55’ 5” Height: 15’ 11” |

| Weight | Tier 3: 87,391lbs Tier 4: 89,949lbs |

| CSS Range | Min: 0.7″ Max: 1.6″ |

1000E Maxtrak

The high performance Powerscreen 1000E Maxtrak Cone Crusher offers operators the flexibility to power the plant either by mains electricity or an on-board genset power-pack. Either power option presents the operator with significant power along with service and maintenance cost savings. This energy efficient and productive machine incorporates the proven 1000 Automax Cone Crusher with direct electric drive, automatic tramp relief, and hydraulic closed side setting (CSS) adjustment.

| Output Potential | 230tph (253 US tph)* |

| Transport Dimensions | Width: 9’10” Length: 55’5″ Height: 11’6″ |

| Working Dimensions | Width: 21’6″ Length: 52’8″ Height: 15’7″ |

| Weight | 99,914lbs |

| CSS Range | Min: 0.7″ Max: 1.6″ |

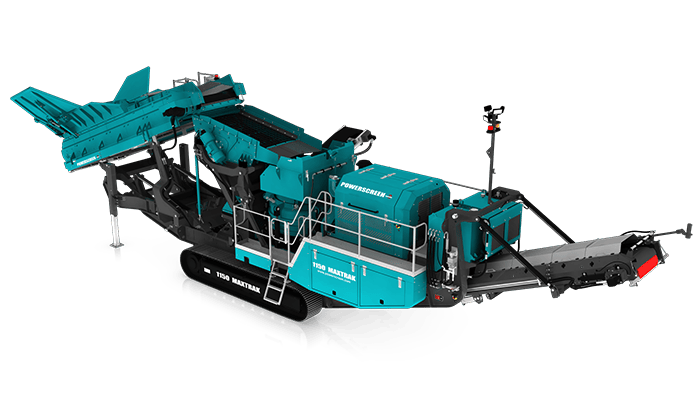

1150 Maxtrak

The Powerscreen 1150 Maxtrak is a high-performance, medium-sized track mobile cone crusher. At the heart of the Maxtrak is the Automax cone crusher with hydraulic setting, tramp release, and an unblocking system. Its unique crushing action provides excellent capacity, high reduction, and good product cubicity for the production of high-quality aggregate and sub-base materials. A level probe over the feed ring regulates the feed belt to ensure the cone chamber is choke fed, essential for maximum reduction, manganese life, and optimal product shape.

| Output Potential | 300tph (330 US tph)* |

| Transport Dimensions | Width: 9’10” Length: 55’5″ Height: 11’10” |

| Working Dimensions | Width: 13’5″ Length: 51’10” Height: 17’1″ |

| Weight | Tier 3: 94,578lbs Tier 4: 94,799lbs |

1150 Maxtrak Pre-screen

The Powerscreen® 1150 Maxtrak Pre-Screen is a high performance, medium sized track mobile rock crusher with an independent pre-screening system. At the heart of the Maxtrak is the Automax® cone crusher with hydraulic setting, tramp release & unblocking system. Its unique crushing action provides excellent capacity, high reduction & good product cubicity for the production of high quality aggregate & sub-base materials. The added pre-screen option allows a sized product or dirt to be removed from the feed prior to entering the cone, thus maximising output capacity and quality.

| Output Potential | 300tph (330 US tph) |

| Transport Dimensions | Width: 9’10” Length: 58’1″ Height: 12’6″ |

| Working Dimensions | Width: 14’2″ Length: 61′ Height: 17’1″ |

| Weight | Tier 3: 114,322lbs Tier 4F: 114,684lbs |

| CSS Range | Min: 0.7″ Max: 1.8″ |

1300 Maxtrak

The Powerscreen® 1300 Maxtrak is a portable cone crushing plant which is ideally suited to secondary applications such as taking an all in feed from a primary crusher. Based around the 1300 Automax® cone crusher, the plant excels in the production of sub-base or aggregates, providing excellent cubicity, throughput and reduction ratios. This cone crusher comes standard with Powerscreen Pulse Telematics and offers high performance, consistent end product, and great fuel efficiency.

| Output Potential | 350tph (386 US tph)* |

| Transport Dimensions | Width: 9’10 Length: 50’4″ Height: 12’8″ |

| Working Dimensions | Width: 12’8″ Length: 50’10” Height: 15’5″ |

| Weight | 105,865lbs (Tier 3) – 105,557lbs (Tier 4) |

| CSS Range | Min: 1″ Max: 1.8″ |

1400 Maxtrak

The Powerscreen 1400 Maxtrak is a large sized track mobile cone crusher, ideally suited to secondary applications such as taking an all-in feed from a primary crusher. The 1400 Maxtrak is fitted with the Terex MVP450X cone chamber and excels in the production of sub-base or aggregates, providing excellent cubicity, throughput, and reduction ratios.

| Output Potential | 700 tph (772 US tph) |

| Transport Dimensions | Width: 9’10” Length: 55’9″ Height: 13’1″ |

| Working Dimensions | Width: 13’9″ Length: 60’8″ Height: 19’8″ |

| Weight | 132,851lbs |

| CSS Range | Min: 1/4″ Max: 3″ |

Do you need more information or a quote?

Fill out the form to the right and one of our Team Members will be in touch.