Smarter Sand Washing

Cyclones, Dewatering Screens, & Screw Washers That Work Harder For You.

Still Losing Sand to Your Pond?

Every day, producers across B.C. are watching fine sand and profits slip away with their wastewater.

Whether you’re running a gravel pit, recycling Hydrovac spoils, or prepping material for construction use, there’s one truth you can’t escape: clean, well-classified sand sells and muddy, oversized piles don’t.

Why Sand Washing and Classifying Matter

When it comes to aggregate production, it’s not just about how much material you process, it’s about how much value you recover. Unwashed material is full of clay, silt, organics, and ultra-fines that downgrade your final product and jam up your equipment. If you’re not washing and classifying properly, you’re:

Hauling and stockpiling more than you need

Paying to dispose of sellable material

Missing out on premium sand markets

The right wash plant can cut your waste, improve product quality, and open new revenue streams—with less water, less downtime, and fewer headaches.

Reduce Waste

Recover more usable sand and keep it out of the pond. Smarter classification means less product lost; less cleanup.

Boost Profits

More yield, drier sand, fewer hours lost to rehandling—this is how you make every ton count.

Protect Equipment

Cleaner discharge reduces wear and tear on stackers, bearings, and belts—helping your machines last longer.

Choose the Right Wash System for Your Operation

There’s no one-size-fits-all. That’s why we carry the full range, from traditional sand screws to modern cyclone-based systems with dewatering screens. Here’s how they compare:

Cyclone + Dewatering Screen

Maximum recovery. Minimal moisture.

Uses centrifugal force to separate valuable sand from water and ultra-fines

Fine material stays in your stockpile—not your pond

Produces drip-free sand at just 14–15% moisture

Low maintenance—no augers, no gearbox, no constant shoe replacement

Perfect for: High-production operations, tight pond space, and producers who want to keep their fines, not flush them.

Wet Screen / Sand Screw Washers

Reliable but limited.

Uses a slow-turning auger to lift sand out of a slurry tub

Struggles to recover finer sand sizes

Produces wetter product with messy discharge

Higher maintenance—frequent wear part replacement and more downtime

Best for: Simpler applications where yield loss and water use aren’t a concern.

Let’s Get Technical

When choosing between a cyclone system and a screw washer, here’s what you need to know:

| Feature | Cyclone + Dewatering Screen | Screw Washer |

|---|---|---|

| Sand Recovery | High (100–200 mesh) | More Usable Fines Lost |

| Moisture Content | 14–15% | 20%+ |

| Maintenance | Minimal | Moderate |

| Water Use* | Heavy | Moderate |

| Wear Parts | Low | Frequent |

*Water Use vs Water Recovery It’s true, cyclone classifiers combined with dewatering screens use more water than traditional sand screws. But they make up for it by recovering significantly more fines, delivering a much drier, more salable product, and, depending on the setup, often support greater water recycling. In the long run, you’re getting more product and better water management, which means a stronger return on investment.

Upgrade Your Wash Plant

Your sand deserves better than the bottom of the pond.

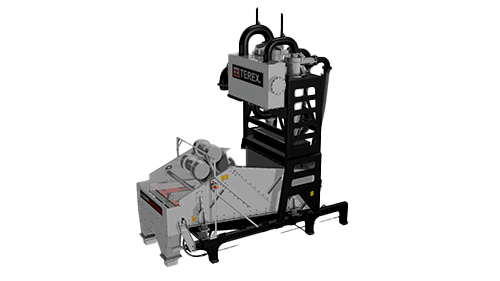

FM Ultra Fines Sand Recovery Equipment

KEY FEATURES

- Underflow rubber-lined slurry pump(s)

- Two rubber-lined hydrocyclone(s)

- Self-regulating cyclone tank

- High-frequency dewatering screen fitted with polyurethane modular mats

- Maximum recovery of material above 75μm (200 mesh)

The Terex FM Compact™ range are static sand washing and classification units that are designed to be cost- and energy-efficient on a single compact chassis.

Using centrifugal force, the hydrocyclone(s) remove clay, silt and slime from sand to bring it into the desired specification. The range combines a collection tank, centrifugal slurry pump(s), hydrocyclone(s) and a dewatering screen to produce up to 2 clean sands.

Bucket Wheel Sand Plant

KEY FEATURES

- Can recover 1 or 2 grades of sand from wet feed or bolt-on boiler box option for direct dry feed

- High capacity variable speed twin bucket wheel providing increased drainage time for a drier product

- Deep fluted variable speed fines screw provides excellent fines recovery

- Anti-turbulence inlet boxes and weir discharge system allows consistently calm settling conditions

The Terex® T 150 is a mobile bucket wheel dewaterer complete with a fines retention screw and twin bucket wheel designed units for removing clays, silts and slimes to produce up to 2 grades of sand.

The T 150 is designed to operate with maximum versatility and can support different requirements such as maximum retention of fines or maximum disposal of fines.

The T 150 can be driven hydraulically from the M Range or its own optional electric power pack.

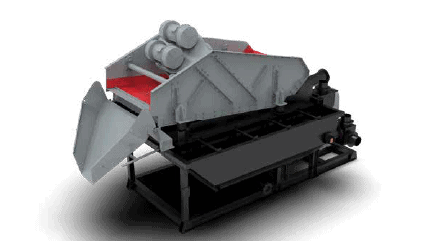

Dewatering Screens

Built to Perform in Demanding Conditions

Terex dewatering screens are engineered with rugged construction to handle a wide variety of applications. While they are primarily used for dewatering and retaining fines, their versatile design allows them to perform effectively across multiple material processing scenarios.

The screen features a 45° sloped back deck with slotted apertures positioned across the flow direction to optimize drainage. The main deck slopes upward at 5°, and efficient vibration is delivered by two exciter motors operating at 980 RPM—ensuring consistent, high-performance output.

Key Features

- Can recover 1 or 2 grades of sand from wet feed or bolt-on boiler box option for direct dry feed

- High capacity variable speed twin bucket wheel providing increased drainage time for a drier product

- Deep fluted variable speed fines screw provides excellent fines recovery

- Anti-turbulence inlet boxes and weir discharge system allow consistently calm settling conditions

Portable Wash Screen & Dewatering Screw

Thorough Material Cleaning

Screens are equipped with strategically placed spray nozzles that ensure thorough scrubbing and clean results every time.

- Each spray bar includes an individual flow valve, giving you complete control over water pressure and usage—so you get cleaner material with less waste.

Efficient, Portable, and Built for Performance

The portable chassis is engineered for hassle-free transport and fast setup—so you can get to work without delays.

Customizable Sand Screw Solutions

Choose from screen sizes ranging from 5’ x 16’ to 6’ x 20’, paired with single or twin dewatering screws for maximum flexibility.

High-Performance Triple Deck Screen

Our triple-deck inclined screen delivers:

3 grades of washed aggregate

1 grade of high-quality sand

Fine Material Screw Washers – Sand Screw

High Capacity Dewatering Screws

Deliver the fine aggregates while chutes and cross conveyors deliver the sized products.

- Heavy duty single or twin dewatering screws (36” x 25”) for high capacity fines recovery.

- Robust I-beam construction chassis with double or triple axle suspension allowing for easy transportation and quick set-up

- Increases throughput – Keeps production moving fast while reducing wear and tear.

SAND SCREW PLANTS – SW100 / SW200 / FMW 5434

The Terex® Fines Materials Washers are specifically engineered to provide the highest quality sand production through efficient washing, classification and dewatering.

SW 100 Sandscrew single screw fine material washer/classifier/dewaterer.

- Recommended maximum material size is 3/8” (10mm).

- Approximate capacity is 50-100 TPH.

SW 200 is a twin screw fine material washer/ classifier/dewaterer.

- Recommended maximum material size is 3/8” (10mm).

- Approximate capacity 100-200 TPH.

Terex FMW5434 Fine Material Screw Washer

The Terex FMW5434 is built for performance, delivering clean, high-quality sand through efficient washing, classification, and dewatering. Designed for durability and precision, this washer features a rugged AR36 steel main frame, reliable Dodge drive and bearing components, and customizable wear shoe configurations. Its tight clearances and rotating shaft ensure aggressive removal of unwanted materials, maximizing sand cleanliness and meeting the demands of modern aggregate operations.

Talk with a washing expert.

We understand that every sand washing and classifying requirement is unique. Our team of experts will work closely with you to tailor a solution that fits your specific needs, ensuring maximum effectiveness.

Give us a call: 1-888-852-9021