RECYCLING & DEWATERING SOLUTIONS FOR HYDRO-EXCAVATION WASTE

Extract maximum value with proven waste recycling solutions that clean and dewater hydro-vac excavation waste.

Introduction to Hydro-vac Excavation Waste Management

What is Hydro Excavation?

Hydro-vac excavation, or hydro excavation, is a non-destructive digging method that uses pressurized water to break up soil and a vacuum system to remove the slurry (mixture of soil and water) from the excavation site. Compared to traditional mechanical excavation methods, this technique is preferred for its precision and reduced risk of damaging underground utilities and other infrastructure like sidewalks and roads.

The challenges related to managing the waste material produced during hydro-vac excavating include:

Disposal and Environmental Concerns

The excavated slurry from hydro excavation is difficult to dispose of due to its solid-liquid state and weight. Most landfill sites are unable to process the material so they refuse to accept it. The slurry must be disposed of properly to avoid environmental contamination. This involves transporting the waste to approved disposal sites, which can be costly and logistically challenging.

Water Usage

The process requires a significant amount of water, which raises concerns about resource conservation, especially in areas with water scarcity.

Storage and Treatment

Temporary storage solutions might be needed for the slurry, especially on larger projects. Additionally, if the slurry contains contaminants, it must be treated before disposal, adding to the complexity and cost of waste management.

Revolutionize Your Waste Management with Hydrovac Waste Recovery and Recycling.

Terex Washing Systems innovative modular washing solution is specifically designed to process Hydro excavated waste material that was typically considered as waste. But with our superior washing process, we can convert it into a saleable product, creating a brand new revenue stream for your business.

- Recover and recycle valuable fines and aggregate materials.

- Recover and repurpose water from hydrovac slurry.

- No more storing or dumping slurry. Recover • Reuse • Recycle.

With years of experience in the industry, we’ve seen firsthand the benefits of our solution. Our Hydrovac Waste Recovery and recycling solution is the future of waste management – join us and see the difference for yourself.

Uncover the story of Capital City Paving‘s transformation in their HydroVac Waste Recycling process, made possible by teaming up with Foreman Equipment and Terex Washing Systems. This successful collaboration has led to an impressive recovery of 80% of sand and gravel. Get to know more about this game-changing partnership and how it’s setting new standards in the industry.

Why Choose Foreman Equipment?

- Industry Leadership: With 40 years of expertise, Foreman Equipment stands as a beacon of innovation and reliability in material processing.

- Cutting-Edge Technology: Our range of Terex Washing Systems equipment is designed to enhance efficiency, from maximizing sand and gravel wash quality to recovering valuable fines and aggregates from construction, demolition, and excavation waste.

- Local Expertise: Our factory-trained team offers personalized, on-the-ground sales, service, and support, ensuring your operations run smoothly and effectively.

Foreman Equipment is the Authorized Dealer for Terex Wash Systems in British Columbia.

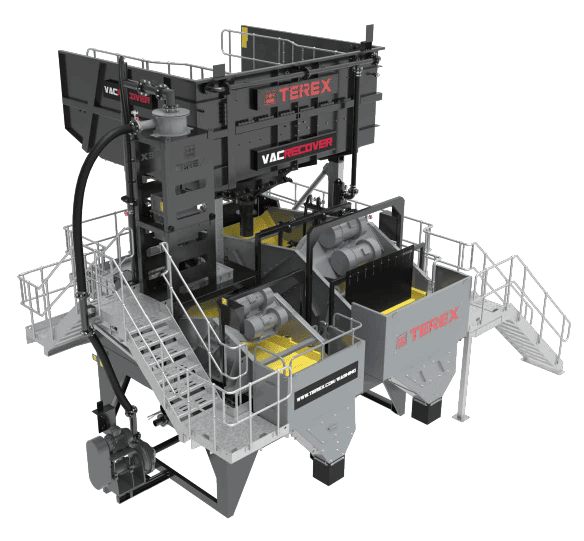

Terex Washing Solutions VacRecover Range

The VacRecover range is a static machine capable of processing wet waste such as Hydrovac, Road Sweepings & Gully waste. A cost and energy efficient machine on a single compact chassis.

The VacRecover range is a static machine capable of processing wet waste such as Hydrovac, Road Sweepings & Gully waste. A cost and energy efficient machine on a single compact chassis.

The VacRecover range is designed for solids/liquids separation for producing a clean dewatered oversize product and a clean dewatered sand product.

Features & Benefits

- Large capacity Reception Hopper is suitable for up to 6 tanker trucks per hour.

- C/W Grid bars, washdown spray bars, walkways and remote HMI controls.

- Underflow controlled by automatic proportional valve

- Multiple hopper options are available.

Components

Chassis

- Ultrasonic tank level control system ensures consistent tank volume and pump run-dry protection

- Built-in anti-turbulence feed sections

- Heavy-duty steel construction

- Easy access to all serviceable areas

Access

- Fully galvanized walkways.

- Access to all serviceable areas.

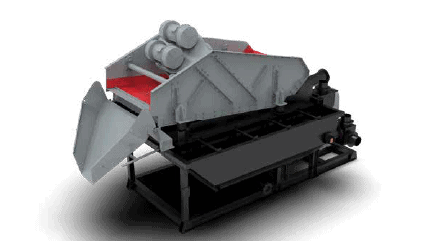

Dewatering Screens

Available in sizes from 2′ x 6′ to 6′ x 14′

- Exceptional dewatering performance

- Heavy-duty frame suitable for surge loading

- Optional Spray bars

- 2 x vibratory motors

- Polyurethane modules and side protection

- Polyurethane low-friction chute liners

- Marshmellow screen mounts for smoother running

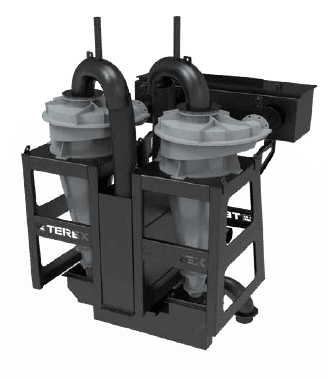

Cyclone/Separator

- Application specific sizes

- Spigot or fish tail discharge

- All wear areas rubber lined

- Pressure flange with gauge and protector

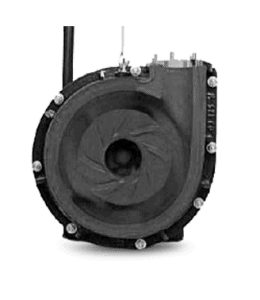

Centrifugal Pumps

- Sized to suit your needs, with numerous combinations of pump and motors

- Abrasion resistant liners

- Moulded rubber impellers

- Pump drain for cold climate applications

- Excellent serviceability

Gallery

Are you ready elevate your Hydro-Vac Waste Recovery and Recycling to the next level?

Talk to one of our Application Specialists today by filling out the form or calling toll-free.

Phone: 604-852-9021