Crushing Rock in the Canadian Arctic with Foreman Equipment and Powerscreen

Far above the tree line, in the isolated community of Gjoa Haven, Nunavut, every load of gravel and every kilometre of road must battle the Arctic itself. Limited access routes and relentless weather make producing construction materials on-site a remarkable challenge

Building the Foundations of Northern Infrastructure

To overcome these challenges, Foreman Equipment partnered with local operators to deliver a fully mobile crushing and screening setup featuring Powerscreen crushers, screeners and conveyors. This innovative solution allows crews to crush rock and manufacture road base materials right where they’re needed—proving that with the right equipment, even Canada’s most isolated communities can build and grow sustainably.

To overcome these challenges, Foreman Equipment partnered with local operators to deliver a fully mobile crushing and screening setup featuring Powerscreen crushers, screeners and conveyors. This innovative solution allows crews to crush rock and manufacture road base materials right where they’re needed—proving that with the right equipment, even Canada’s most isolated communities can build and grow sustainably.

Mobile Crushing Equipment Built for Remote Site Operations

Operating in the Arctic demands machinery that is powerful, reliable, and easy to mobilize. That’s why the team upgraded to a Powerscreen Maxtrak 1000 cone crusher, a Powerscreen Chieftain 1700X screen, and a CT80 conveyor—all supplied and commissioned by Foreman Equipment.

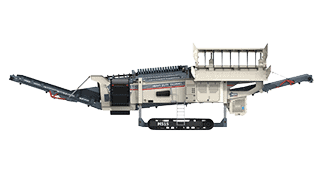

Powerscreen Maxtrak 1000 Mobile Cone Crusher

Delivers consistent, high-quality material gradation for 20 mm road gravel and base material.

Track-mounted design allows flexible operation on rough or frozen terrain.

Ideal for remote projects requiring fast setup and reliable performance.

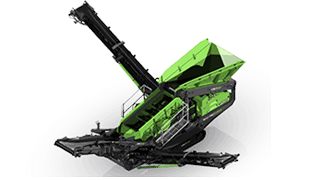

Powerscreen Chieftain 1700X Inclined Screen

Multi-deck system for processing several aggregate sizes at once.

High throughput efficiency designed for demanding Arctic conditions.

Durable build for continuous operation in extreme climates.

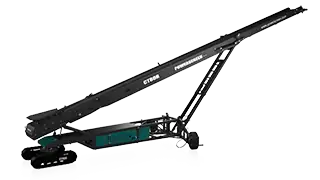

CT80 Mobile Conveyor

Simplifies material handling between crusher and screen.

Reduces the need for loaders and manual re-handling.

Compact, foldable design for transport and quick setup.

Commissioning Mobile Equipment in the Canadian Arctic

Setting up mobile crushing equipment in a remote Arctic location presents unique logistical and environmental challenges. Foreman Equipment’s field technician, James, traveled to Gjoa Haven to oversee the full commissioning process, ensuring each unit was operating at peak efficiency despite the freezing temperatures.

With limited access to spare parts, maintenance facilities, and support infrastructure, reliability and preparation were critical. The successful setup demonstrated how mobile crushing and screening systems enable rapid deployment in even the most remote areas, helping local crews stay productive within tight seasonal windows.

Why the Equipment Upgrade Was Essential

The transition to higher-capacity mobile crushing and screening units allowed the operation to:

Increase production output dramatically to meet local demand.

Achieve consistent, high-quality materials suitable for roads, foundations, and construction.

Reduce reliance on imported aggregates, cutting freight costs and carbon footprint.

Empower local operators to take control of their own infrastructure needs.

This investment not only improved efficiency but also strengthened the community’s self-sufficiency—ensuring projects could move forward without waiting for long, costly shipments from the south.

Paving the Future of Remote Infrastructure Development

Projects like Gjoa Haven mark the beginning of a new era in remote infrastructure development. Foreman Equipment’s partnership with Powerscreen ensures operators across Canada have access to reliable, mobile solutions for crushing, screening, and aggregate production—no matter how challenging the environment.

From the Canadian Arctic to rural job sites, Foreman’s mobile equipment continues to empower communities, drive growth, and build the foundations of the North.

Resilience, Adaptation, and Innovation in Harsh Environments

Operating heavy equipment in Arctic conditions is as much about mindset as machinery. It requires resilience, preparation, and innovation. The Gjoa Haven project showcases the power of mobile crushing solutions that adapt to terrain, weather, and logistical limitations—proof that Foreman Equipment’s mobile systems can deliver real results wherever infrastructure is needed.

By bringing crushing, screening, and conveying capability directly to the source, communities can produce their own materials, reduce project costs, and accelerate development—all while minimizing environmental impact.

Learn More About Mobile Crushing Solutions

Whether you’re working in the Arctic, a mining camp, or a remote construction site, Foreman Equipment offers a complete range of mobile crushing, screening, and washing systems tailored to your needs.

👉 Contact Foreman Equipment to learn more about how our mobile Powerscreen and Terex solutions can help you tackle remote infrastructure challenges with confidence.

Links to Popular Mobile Equipment.

Compact Crushing & Screening

Compact crushers and screeners small enough to fit on the jobsite. Powerful enough for the quarry.

MDS. Rock Trommels

Separate, sort and clean wet, sticky rock up to 32″

Wheel Portable Crushing & Screening

All of the reliability and rugged performace of Powerscreen equipment, on a wheeled chassis.