Quick Summary

Still messing with sludge ponds? The Terex Filterpress is your upgrade, it recovers up to 95% of your water, produces dry cakes with up to 85% solids, and automates the whole process. No more wasted water, no more wasted time. If you’re still hauling sludge, you’re hauling away profits.

Your Wash Plant’s Dirty Little Secret

Ever seen a job site drowning in dirty water and sludge piles like it’s stuck in the Stone Age?

Yeah, we’ve seen it too.

Ponds full of murky runoff. Trucks hauling dripping sludge to the dump. Thousands of gallons of water wasted every day. It’s messy, expensive, and outdated especially when every drop of water and every load of waste is money you’re flushing away.

And let’s not even get into the permitting nightmares or the footprint of a traditional pond setup if you’re operating in an urban area.

What Sludge Is Really Stealing from You

Here’s what you need to know: while you’re managing all that waste, you’re also missing out on something way more valuable: efficiency.

Every minute your crew spends babying sludge, every penny you spend on water bills, every load sent off to disposal is productivity and profit you’re not reclaiming.

And it’s not just about the bottom line. It’s about future-proofing your site. Environmental expectations are rising. Water use is under scrutiny. And if your competitors are running lean, clean, and automated, you’re already behind.

Filterpress Tech That Pays for Itself

Enter the Terex Washing Systems Filterpress — your secret weapon for turning waste into wins.

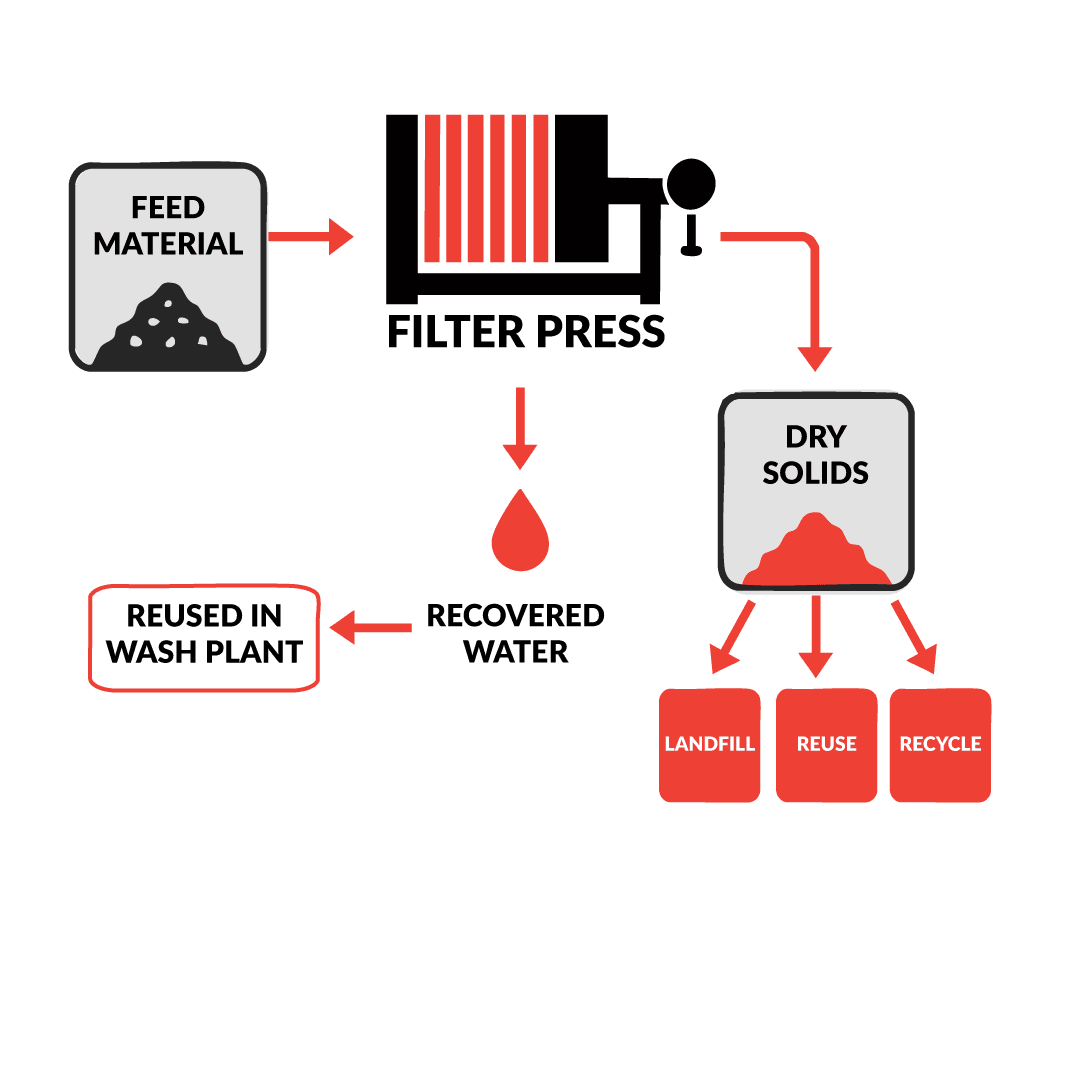

This beast recovers up to 95% of your process water and transforms sludge into dry solids with up to 85% dryness. That means:

Less water hauling

Less sludge disposal

Less downtime

More uptime, more throughput, more profit

It’s fully automated, PLC-controlled, and built with zero-hydraulic design to eliminate oil contamination risk. It even cleans itself, thanks to a robotic cloth wash system that keeps your cycles fast and your crew out of the splash zone.

Need remote access? You got it. Want a smart interface that talks to the rest of your TWS system? Check. And with premium European-built plates and stainless everything, it’s made to run hard without running into issues.

Big site or tight site, urban or remote — this thing is a compact, high-performance solution that makes sludge management look easy.

FILTER PRESS FLOWCHART

From Dirty Slurry To Clean Profit

Key Benefits at a Glance

✅ Recycles up to 95% of process water

✅ Delivers dry cakes with up to 85% solids

✅ No hydraulics = no mess

✅ Automated cloth washing system

✅ PLC and remote diagnostics

✅ Compact footprint for urban or remote sites

✅ Built tough for aggregates, C&D, and recycling industries