Cyclones vs Sand Screws: The Ultimate Guide to Smarter Sand Separation

Why the Right Separator Really Matters

Let’s be honest, choosing the right sand classifier machine to separate your material can make or break your operation. Whether you’re trying to hit spec, stay ahead of environmental rules, or just clean up a messy site, your separator is a big part of the equation. Two of the big players? Sand screws and cyclones. Both have their perks, but which one’s right for you? Let’s break it down in plain English.

Sand Screws: The Old Reliable Workhorse

If you’ve been in the game a while, you’ve probably run a sand screw. They’re tough, forgiving, and dead simple to operate. They handle coarse, abrasive feed like a champ and don’t freak out when the feed isn’t consistent. Plus, they won’t break the bank upfront, and they’re relatively easy to maintain.

But here’s the thing, sand screws have a tendency to toss fine and ultra-fine particles into the settling pond. That means you’re literally washing product and profit, down the drain. They also leave your sand pretty wet, which leads to sloppy conveyors, gummed-up bearings, and more site cleanup than anyone wants.

What’s That Really Costing You?

Every grain of usable material that slips away with your process water is money lost. Add in the time and cost of replacing wear parts, babysitting gearboxes, and dragging hoses around to clean up wet messes, and you’ve got a real productivity problem on your hands.

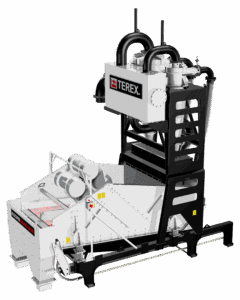

Cyclones: Cleaner, Drier, Smarter

Cyclones are like the brainy upgrade to your old-school screw. Instead of dragging sand up an incline, they use centrifugal force to separate the fines out of your slurry. And they’re good—really good—at it.

Cyclones are like the brainy upgrade to your old-school screw. Instead of dragging sand up an incline, they use centrifugal force to separate the fines out of your slurry. And they’re good—really good—at it.

When paired with a dewatering screen, cyclones produce sand that’s drier and easier to handle—typically around 14–15% moisture. That means fewer puddles, cleaner conveyors, and happier bearings. And because they don’t have augers or gearboxes, maintenance is minimal. Just pumps and vibratory motors.

So… Which One Should You Choose?

It really comes down to your operation:

Stick with Sand Screws if you’re a smaller contractor, working with coarse material, and you need something rugged and simple.

Upgrade to Cyclones if you’re losing fines, wrestling with water restrictions, or under pressure to meet tight product specs and environmental rules. They may take a little more attention to set up, but the long-term payoff is big.

Water Use vs. Water Recovery

Yes, cyclone systems use more water than sand screws. But here’s the tradeoff: they recover way more fines, give you a drier, more marketable product, and—depending on your setup, can actually improve your water recycling game. In short, it’s a smarter use of water that pays you back.

Good for Business, Good for the Planet

With regulations tightening and water becoming an increasingly valuable resource, cyclone systems make it easier to stay compliant. They reduce your pond size, clean up your site, and cut down your water loss, all while helping you recover more sellable material.

The Bottom Line

Sand screws aren’t obsolete, but if your operation is pushing for tighter specs, better margins, and smarter water use, it’s worth asking:

Are you settling for “good enough”? Or are you ready to recover more, dry faster, and scale up for the future?

Let’s Get You Set Up Right

At Foreman Equipment, we’ve helped many producers switch to cyclone-based systems. They recover more, run cleaner, and save money in the long haul.

Fill out the form, or give us a call.